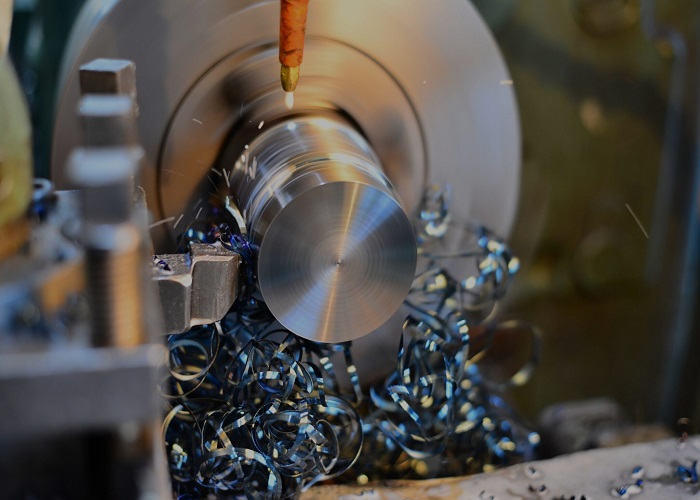

Precision and efficiency are a necessity in the manufacturing world. This is where Computer Numerical Control (CNC) engineering services will help. Industries that work with CNC services providers can increase precision and speed up production Across the globe, small, medium, and big enterprises in the manufacturing sector are transforming their production, simply by incorporating computer numerically controlled systems.

CNC engineering does not only encompass the automation of some processes but seeks to optimize all the manufacturing processes to achieve the best result. Using this technology helps assure that every component is made precisely as required—to minimize mistakes and wasted material.

Key Benefits of Integrating CNC Engineering Services

It is important to note that the use of CNC engineering services in your manufacturing processes has many benefits. One of the most noticeable positive effects is that it provides greater precision. CNC machines work with high precision thus products are not likely to have many flaws and more materials are not used.

Another advantage is repeatability. After programming a design on a CNC machine, it can replicate the same part in the hundreds, if not thousands, in a very short time, without significant variations, which makes it ideal for large-scale production.

Optimizing Production Workflow with CNC Technology

With CNC machines incorporated into factories, industries can minimize tedious, repetitive tasks that would have been done by manual labor, and have them done by a machine instead, reducing the possibility of mistakes or tedious work. This not only contributes to the enhancement of production rates but also optimizes the efficiency of the flow. The management of resources is also better as CNC machines can estimate the amount of material required before a project, and therefore the likelihood of wastage is minimized. CNC technology also makes it possible to achieve faster tooling and tooling replacement, another significant factor in adherence to strict production timelines.

Improving Product Quality With the Help of Contemporary CNC Technologies

Furthermore, CNC engineering services are precise, and this high level of precision has a direct effect on the quality of the products being manufactured. CNC machines operate according to the set plans, thus have the ability to handle various patterns and architectural work that would be very difficult to accomplish by hand. This capability is particularly relevant in industries that deal with products that need to conform to set standards of compliance. Essentially, CNC helps manufacturers to maintain high levels of quality that are in compliance with contracts, making clients confident in the produced goods.

Conclusion

The usage of CNC engineering services provide a revolutionary prospect for manufacturing operations. CNC is proven to offer accuracy, reduced wastage, improved product quality and efficient workflow, which are very important for any manufacturer who wants to produce high-quality products in the current market. Hiring CNC engineering service providers provides companies with an opportunity to enhance not only work productivity but also the quality that is required in the contemporary market.

Through the adoption of CNC engineering, manufacturing industries can enhance their production capacity, ensuring that they are able to maintain competitiveness in the market through innovations.